Features:

- A 95% reduction in the water used is normal when compared to constant flow immersion sterilisers.

- Therefore at least a 95% reduction in the cost of heating the water.

- Virtually no steam produced, to condense on overhead equipment and drip onto carcasses.

- No tank of hot water, zero risk of scolding and more comfortable to work next to.

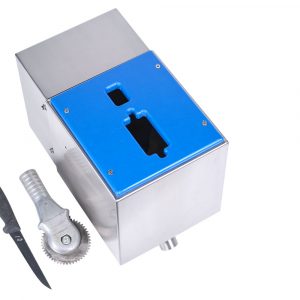

- Activated by insertion of the Knife into the unit. Safe and easy for operators.

- Fully automatic operation gives consistent results with any operator.

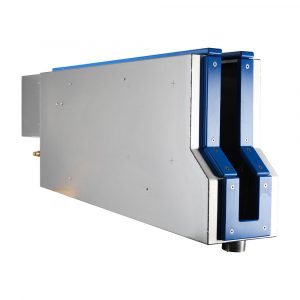

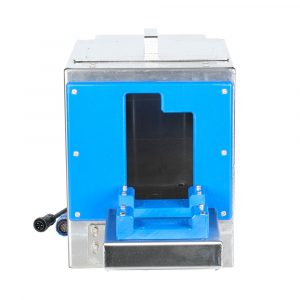

- New cassette design allows for ease of servicing, minimising down time

- New knives hold their edge longer because they aren’t sitting in a tank of hot water which anneals them

- Built-in electric water heater which means the water supply can be anything from cold 0°C/32°F upto 90°C/180°F and the built-in water heater will ensure that it is above 82°C/180°F

- Using the built-in water heater to heat the water is by far the least expensive way to heat the water as it only heats the water that is used no more no less.

- Electric from a renewable source can now be used for sterilisation of knives and tools helping users to reduce their dependence on fossil fuels and reducing their carbon footprint.

Options:

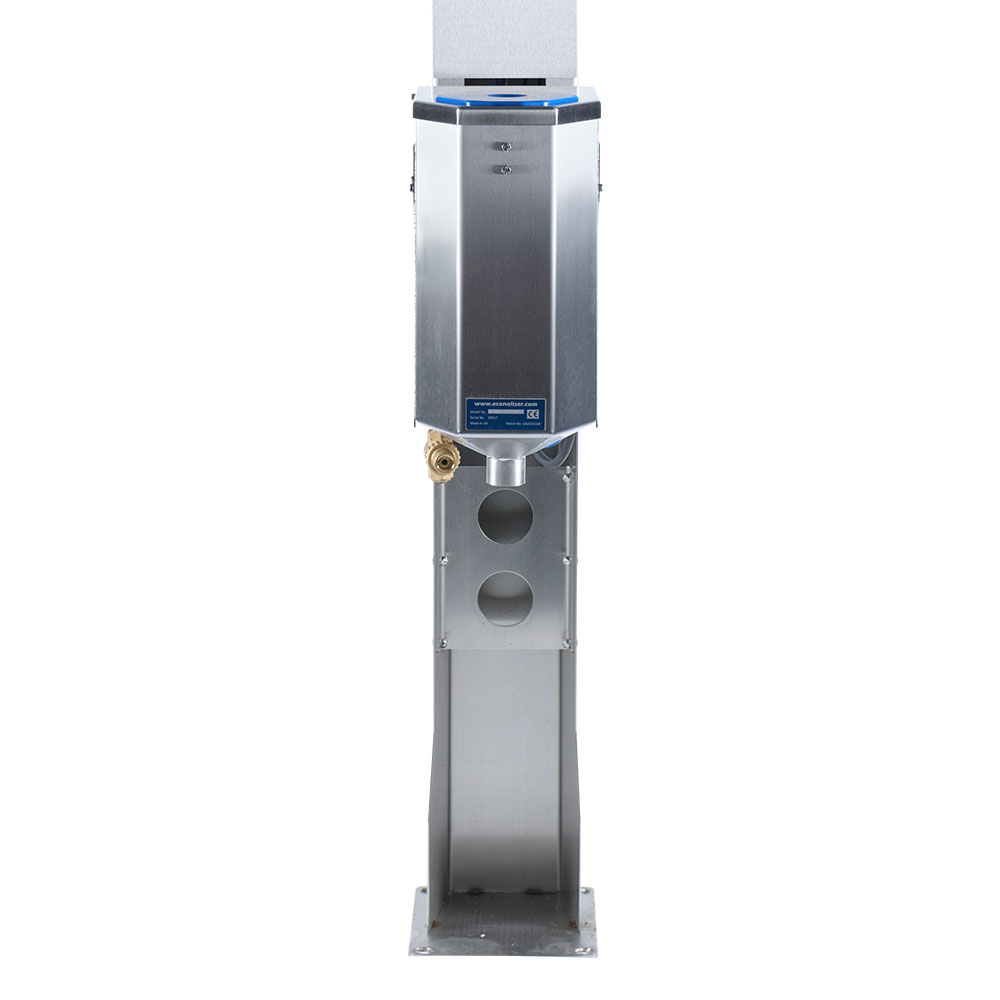

- Mounting Coloumn

- External temp display shows temperature of the water being sprayed.

- 4 nozzle manifold for longer knives

- Special manifold for exceptionally dirty knives

Specification

- Mains Electric supply 230/240Vac 50/60Hz

- Max load :- 11A

- Water supply:- ≥82°C/180°F

- Dynamic Water Pressure min:- 3Bar/45psi

- Sterilisation Min water Flow rate:- 4.2L/min or 1 Gal/min

- Sterilisation Cycle time Factory set:- 4.5secs

- Sterilisation Water used per cycle:-0.140Ltrs or 4.75Fl oz

Reviews

There are no reviews yet.