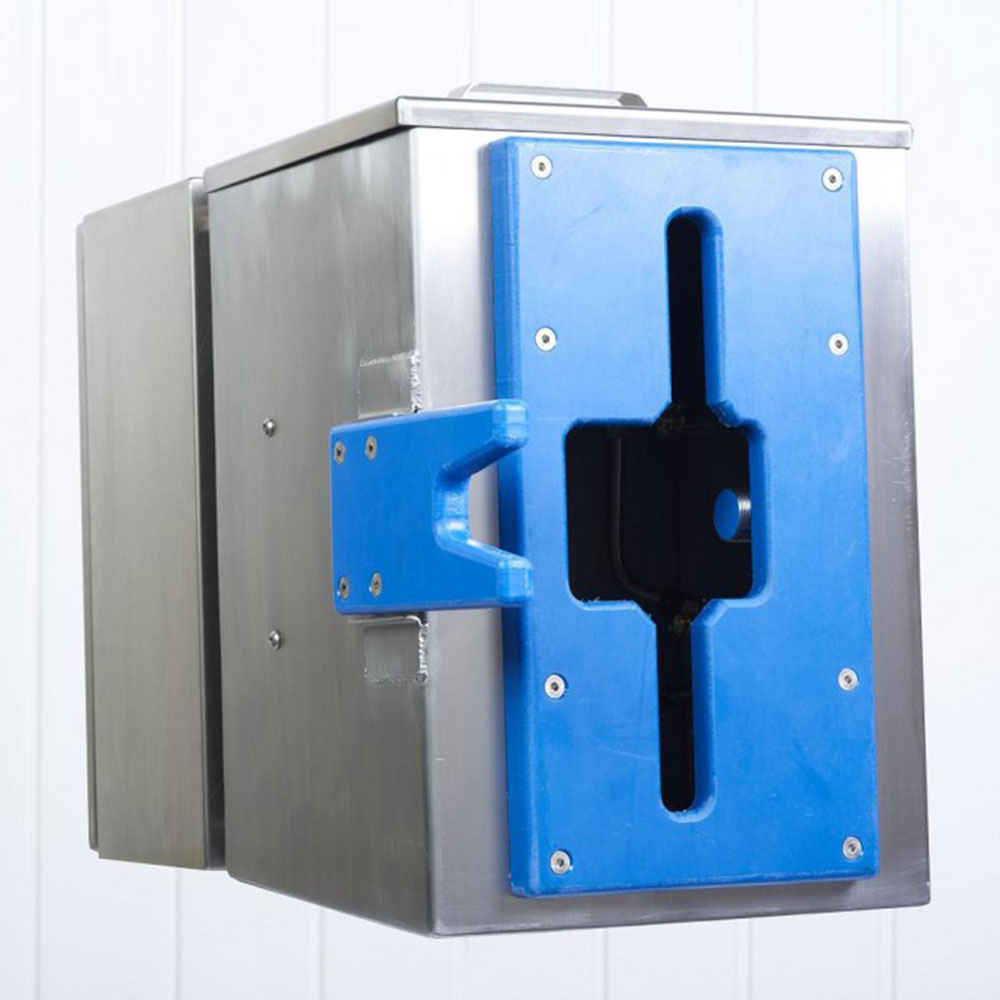

Features:

- Water is only used during the sterilisation cycle, representing a massive reduction in water and energy compared to constant flow or water bath types

- Tool is left cleaner than with traditional methods

- Virtually no steam, to condense on equipment and drip onto meat

- Uses absolutely no water when production line is not running

- Virtually no ambient heat produced, reducing running cost in refrigerated areas

- Fully automatic operation, produce consistent test results with all operators

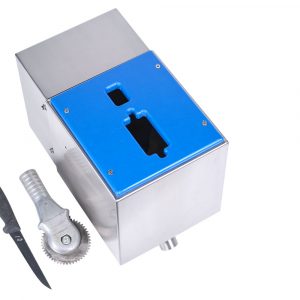

- Activated by insertion of the hock cutter tool, easy and safe for operators to use

- Temperature and cycle time adjustable for optimum efficiency

- Designed with ease of servicing in mind to minimise down-time

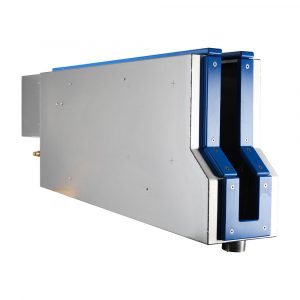

- 2mm 304 grade stainless steel construction- robustly built for abattoirs

- Designed and manufactured in Northern Ireland, sold worldwide

Options:

- Basic unit for areas with an 82⁰C water ring main

- Electric unit for areas with inconsistent or <82⁰C water supply

- Basic and electric units can be supplied free-standing or mountable

Reviews

There are no reviews yet.